Manufacturing Process of Enameled Products

"Providing good products"

is the mission of TAKARA STANDARD's factory.

We regarded contributing to the improvement of everyone's quality of life as our top priority. In our quest, we came across an unprecedented material: a high-quality enamel.

Only enameled products can provide the unprecedented comfortable feeling.

To manufacture the enamel products to be "loved" by customers all the time, TAKARA STANDARD gives the utmost importance to the quality of products. We also believe in the power of experienced human workers. They actually check the products with their eyes and hands for quality, then finalizing the products.

The flow of each manufacturing process is similar to handing a relay baton from person to person. During the process, products in progress are moved from person to person to finalize them. Many workers involved in finalizing the products and can maintain high quality.

Enamel is like a form of living being. The processing conditions need adjustments depending on the environmental factors such as temperature and humidity for working time. Fine adjustments to such subtle changes during daily work is possible only by operators rather than machines.

"Providing reliable quality products"

This mission is essential for manufacturing the products to be "loved" by customers indefinitely.

The enameled products have reasons to be "loved" all the time.

-

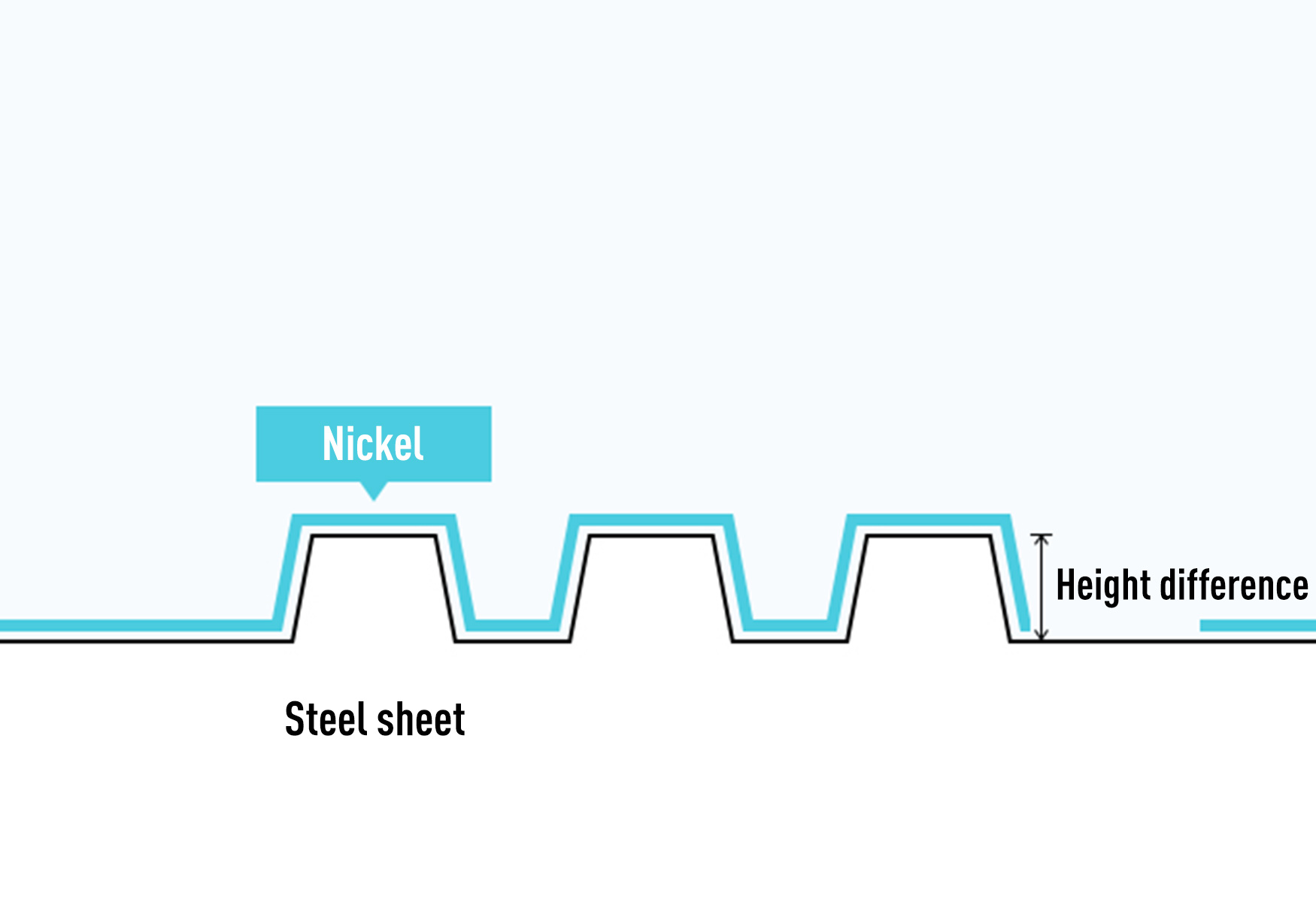

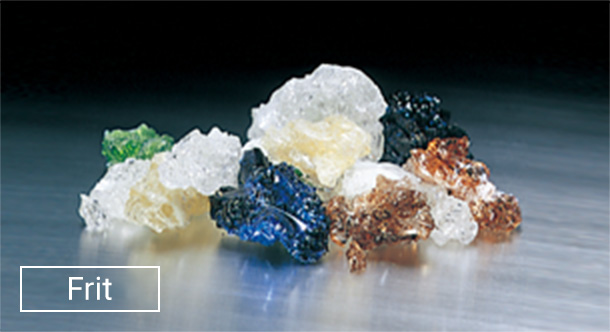

What is enamel?

Enamel is a dreamy integration of steel and vitreous material, taking full advantage of both the former's strength and the latter's beauty; it is manufactured by baking vitreous glaze sprayed on the surface of steel, aluminum and others.

-

What most influences the quality of enamel?

The "high-quality enamel" developed by TAKARA STANDARD is an unprecedented, unique material, characteristic of high technologies shown in the above Point 1 and 2.

TAKARA STANDARD's high quality enameled products have a variety of applications:

kitchen, range hood, kitchen panel, washstand, wall panel of system bath, interior/exterior material, and others.

The enameled products are excellent in cleanability and durability with longer cleanness.

The attractive feature of enamel is essential for manufacturing the products to be "loved" by customers indefinitely.

"Providing reliable quality products"

TAKARA STANDARD will continue to grow to fulfill this mission in the future.