Sustainability

Environment Initiatives

Environmental Policy

Takara Environmental Policy

Takara Standard considers environmental protection a priority issue in management. We strive to reduce the environmental impact of our business activities and have initiatives to protect the environment and prevent pollution in order to contribute to the realization of sustainable society.

- We develop products and services with low environmental impact.

- We have initiatives to reduce environmental impact in all business activities.

- In addition to complying with environmental laws and regulations, we take on environmental problems in response to society’s demands.

Target for CO2 Reduction

- CO2 emission reduction target for FY2030

- Reduction of 30% from FY2020 level

Initiatives to Reduce CO2 Emissions in Business Activities

Installation of energy-saving equipment at production bases, conversion of fuels

At the factories of enameled products, the baking furnaces used in the manufacturing

process consume a lot of energy. Initiatives to reduce energy consumption include

increasing the use of high-heat insulators and reusing the waste heat from baking

furnaces.

We are also striving to reduce gas consumption and CO2 emissions by replacing gas

burners for the baking furnaces with energy-saving ones to improve combustion

efficiency.

At the Kanto Factory, where resin products are manufactured, we are switching from

electric boilers to gas boilers as the heat source of facilities used in the

manufacturing process of resin products.

This initiative is reducing energy consumption and CO2 emissions.

Installation of energy-saving equipment at our offices

At our business offices, factories, distribution centers, and other bases, we are switching to LED lights and installing high-efficiency air conditioners.

TCFD-Based Information Disclosure

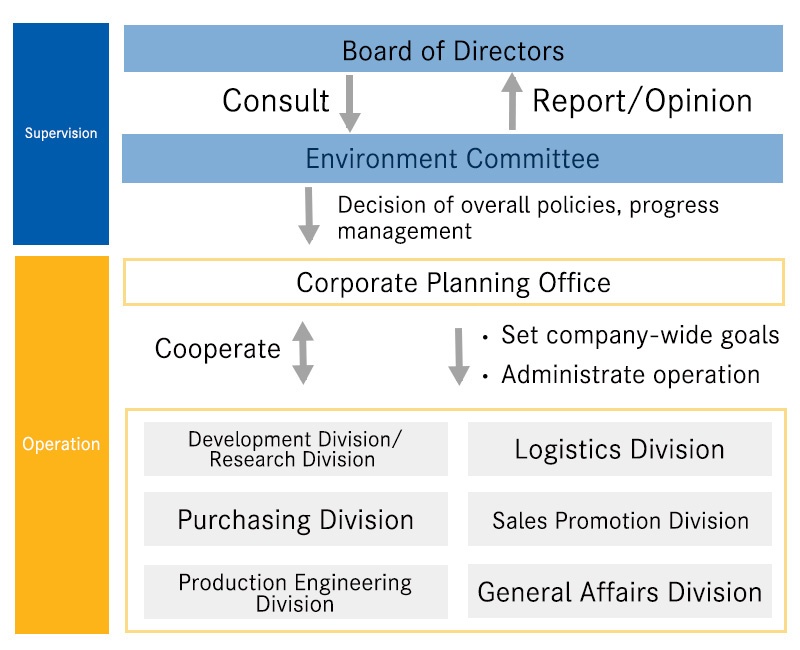

Governance and risk management

Recognizing that taking action on sustainability is a priority issue in our management, we will

contribute to the realization of a sustainable society through our business.

In July 2022, we created the Environment Committee, chaired by the executive in charge of

Corporate Planning Office . The Committee examines environmental issues and policies, mainly

regarding climate change. The Committee consists of directors of the Headquarters to build up a

discussion system cross-sectionally.

Convening at least twice a year, the Committee discusses and approves responses to the TCFD

recommendations, confirms the progress on strategy and metrics, ensures coherence with the

management plan, and submits a report to the Board of Directors at least once a year. The Board

of Directors conducts decision-making on important matters and supervision based on the opinions

and reports of the Committee.

The Corporate Planning Office, the secretariat of the Committee, operates the Committee, and

coordinates with company divisions in responding to the TCFD recommendations and monitoring

these responses. The Office also uses scenario analysis to identify the risks and opportunities

that arise from climate change, considers responses, and makes suggestions and reports to the

Environment Committee.

Roles and Constituents of Each Organization

Environment Committee

| Constituents | Chair | The executive in charge of Corporate Planning Office |

|---|---|---|

| Members | Directors of Administration Headquarters, Production and Logistics Headquarters, Sales Headquarters, Research and Development Headquarters, and Corporate Planning Office | |

| Secretariat | Corporate Planning Office | |

| Activities | Regular meetings | Twice a year (semiannual) |

| Themes | Decision of company-wide policies, risk management, decision of strategies, decision of goals, progress management of the action plan |

Operation structure (meetings of Environmental Promotion Leaders)

| Constituents | Each division | Environmental Promotion Leaders are chosen from each division |

|---|---|---|

| Activities | Regular meetings | Four times a year (once every three months) |

| Corporate Planning Office | Secretariat of the Committee, incorporation of risks and opportunities, establishment of strategies | |

| Each division | Setting goals toward the implementation of strategies, proposing implementation plans, managing progress |

Strategy

Transition risk(less than 1.5℃ scenario)

| Category | Scenario | Risk | Impact | Opportunity | Impact |

|---|---|---|---|---|---|

| Policies/ regulations | Introduction of carbon tax | Increased manufacturing costs and selling expenses due to increased procurement costs of materials and energy | Large | - | - |

| Stricter regulations on forest environment | Increased manufacturing costs due to increased difficulty and cost of procuring wood | Large | - | - | |

| Markets/ technologies |

Progression in divestment and revision of business portfolio toward

decarbonization in the petrochemical and iron and

steel industries steel industries

|

Increased manufacturing costs due to increased difficulty and cost of procuring steel, resin, and wood | Large | - | - |

| Diversifying needs for wood | - | - | |||

| Change in behavior of regular clients and consumers Preference for products with water- or energy-saving features, or longer service life |

- | - | Higher presence of enameled products, etc. due to ease of maintenance and longer service life | Medium | |

| Change in behavior of regular clients Preference for materials that emit less GHG in the manufacturing process |

Risk of decreasing need for products that emit larger amount of GHG in the manufacturing process | Medium | Increased need for wooden products | Medium |

Physical risk(4℃ scenario)

| Category | Scenario | Risk | Impact | Opportunity | Impact |

|---|---|---|---|---|---|

| Chronic | Increased risk of heatstroke due to higher temperatures | A certain amount of impact will occur, although the work environment is not in direct sunlight | Medium | - | - |

| Acute | Increased severity and frequency of abnormal weather | Shutdown due to a disaster Supply chain interruption due to a disaster |

Small | Higher presence of our strong supply structure in the face of the increased risk

of a disaster (Supply was not interrupted at the time of the large earthquakes in 2011) |

Large |

Main initiatives to address the environmental problems

| Aim | Responses |

|---|---|

| Reduction of GHG emissions | Installing solar panels, driving a modal shift (greater use of green shipping and trains) |

| Enhancing resilience in the case of a weather-related disaster | Carrying out ongoing BCP initiatives such as decentralizing manufacturing and logistics bases and ensuring sufficient inventory |

| Saving resources in packaging materials | By using the minimum amount of packaging, saving resources, reducing waste, and improving efficiency of transportation and unpacking |

Indexes and Targets

The calculated amount of GHG emissions of the Company (Scope 1+2) and its reduction target are shown below. To contribute to the realization of a decarbonized society, we are considering concrete reduction measures.

| FY2020 | FY2021 | Target | |

|---|---|---|---|

| FY2030 | |||

| Scope1+2 | 58,941 tCO2 | 62,278 tCO2 | -30%(from FY2020 level) |

* The amount of GHG emissions is calculated based on the “Greenhouse Gas Emissions Calculation and Reporting Manual,” published on the website of the Ministry of the Environment.