Enamel is our heart and soul

manufacturing

Takara standard's mission

Our mission is to deliver superb products to the customer

Takara standard’s dedication to quality comes from its desire to make products that keep customers happy for years.

That’s why our workers confirm quality by carefully seeing and touching each and every detail.

The production process is like a relay, with the baton passed on from person to person to reach a product’s finish line.

High quality in the finished product is ensured by having specialized participants confirm each stage of production.

As well, enamel is like a living thing.

Depending on the conditions—temperature, humidity, others—on a particular day,

it must be processed accordingly.

Because it’s hard for machines to adapt to these delicate daily changes, people are a crucial part of production.

We want customers to be happy with our products for years to come.

That’s why we pay meticulous attention to quality.

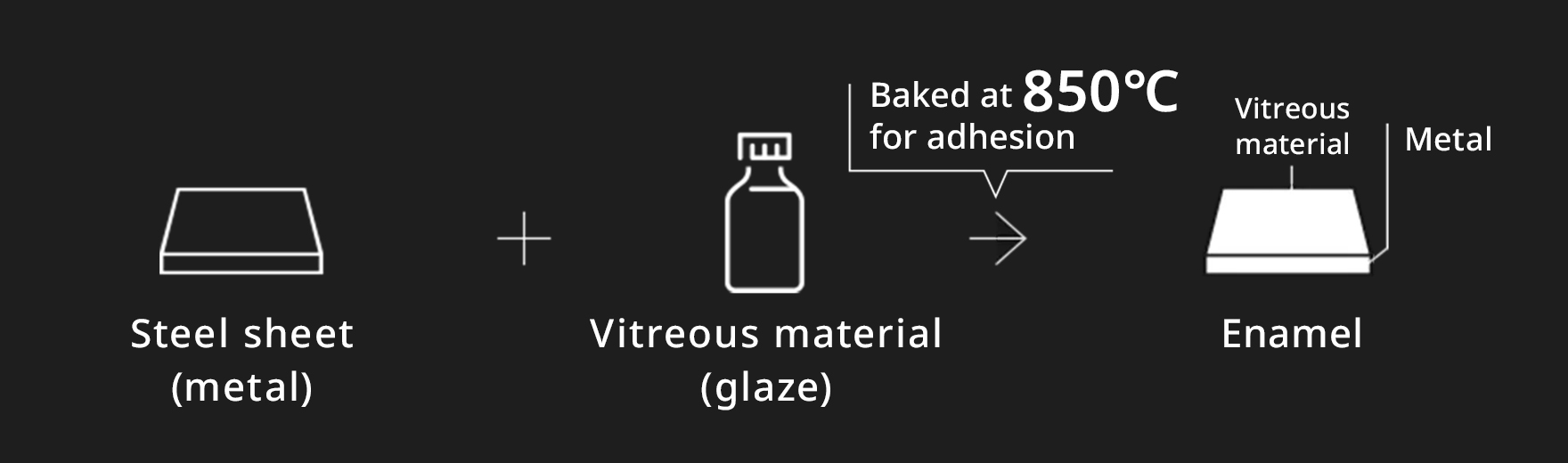

Just what is enamel?

An integration of metal and vitreous material, enamel is an ideal material.

It leverages the advantages of each: the strength of metal and the beauty of glass.

To make enamel, a vitreous glaze is sprayed onto the surface of a metal like steel or aluminum,

and this is then baked at a high temperature.

Factors affecting the quality of enamel

-

Factor1

Integration and adhesion of steel and vitreous material, two different materials

-

Factor2

Quality of the materials themselves

Takara standard’s high-grade enamel is a unique,

first-of-a-kind material developed by using advanced technologies to satisfy both of these factors.

Process of making enamel products

-

PROCESS 1

PROCESS 1Steel sheet for enamel

Enamel products start with steel sheet.

The cabinets for kitchens and washstands are made from steel coils and the walls of bathrooms are made from sheet steel.Takara standard technology

To make high-grade enamel, you need to use steel with minimal impurities and strengthen the adhesion between the steel and the glaze.

We use highly pure, ultra-low-carbon steel jointly developed with a steel manufacturer. -

PROCESS 2

PROCESS 2Steel sheet processing

The steel is processed to match its application.

The processed steel is welded by robots.Takara standard technology

The forming of steel into complex shapes is carried out by experienced humans since it is too difficult for robots to perform.

-

PROCESS 3

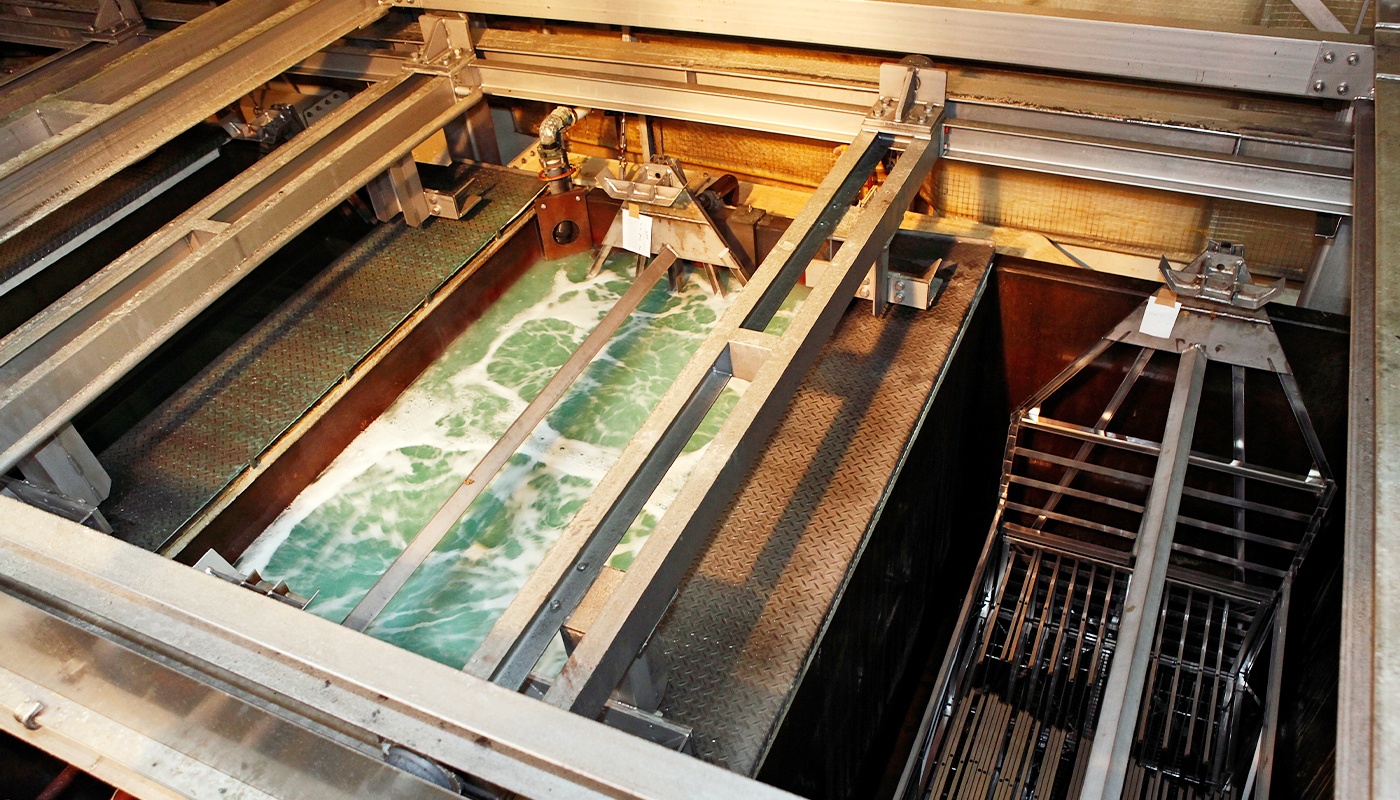

PROCESS 3Pretreatment

To strengthen the adhesion between the steel and vitreous glaze, the steel undergoes pretreatment in which degreasing, pickling, nickel deposition, and neutralization occur.

Degreasing

Oil stuck to the steel is removed.

Pickling

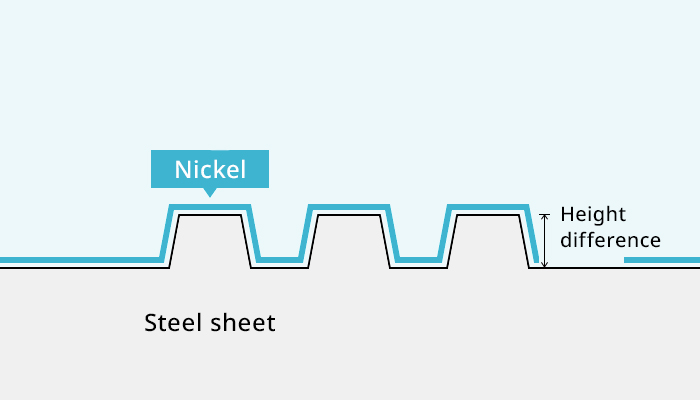

The steel is dipped in sulfuric acid to give its surface a micro-level roughness.

This increases the surface area that comes in contact with vitreous glaze, thus strengthening the adhesion between the steel and glaze.Takara standard technology

The steel sheet is jointly developed with a dedicated manufacturer.

This steel sheet can be given micro-level roughness on its surface, exhibits minimal foaming, and has good adhesion to the glaze.

These characteristics result in high-grade enamel.The larger the height difference between the hills and valleys of the rough surface, the larger the contact area between the steel and the glaze, and the greater the adhesive strength.

Nickel deposition

Nickel is deposited on the steel sheet to chemically enhance the adhesion between it and the glaze.

Neutralization

Pickling and nickel deposition involve submersion in acidic solutions.

To prevent the steel sheet from rusting, it is neutralized in an alkaline solution.Takara standard technology

The proper nickel concentration, time, and temperature in the nickel deposition process are technologies accumulated through Takara standard’s expertise.

-

PROCESS 4

PROCESS 4Glaze manufacturing

Formulation and mixture of frit

A glaze is a coat consisting of a mixture of glass powder and additives. The ingredients of the glaze (silica, fieldspar, borax, soda ash, etc.) are formulated and mixed at an appropriate ratio.

Takara standard technology

The formulation of the glaze’s ingredients is a crucial step in determining the quality of the enamel. Depending on the product application, there are approximately 600 unique formulations for giving the specifications required (performance, color, gloss, productivity, etc.).

To make enamel in bright colors such as pastels, more advanced coloring techniques are required, such as confining metal ions in glass and forming crystals.Fusing of frit

The raw materials are fused at 1,200 to 1,300°C.

The vitreous substance manufactured by rapidly cooling and milling the fused compositions is called frit. There are two manufacturing methods. Frit mass production uses a continuous fusing furnace, and batch production (for making small quantities of numerous varieties) uses a crucible furnace.Milling of frit

After adding clay, water, various chemicals, and other ingredients, the frit is thoroughly crushed and ground to form a muddy glaze.

-

PROCESS 5

PROCESS 5Enameling

Glaze is uniformly sprayed on the pretreated steel. The steel sheet is then thoroughly dried to remove moisture before baking. If the glaze still contains moisture when it is put into the furnace, the steel sheet will likely lose the uniformity of its coating due to the moisture evaporating.

Takara standard technology

Glaze application determines the quality of the enamel, so we use proprietary technology in visually checking this process and spraying the glaze uniformly on the steel sheet.

Glaze application will use a variety of methods depending on the size and shape of the product parts: an electrostatic method, in which high voltages are applied to the glaze to enable electrical adhesion to the steel sheet; a spray method using spray guns; or a dipping method in which steel sheets are dipped directly into the glaze. -

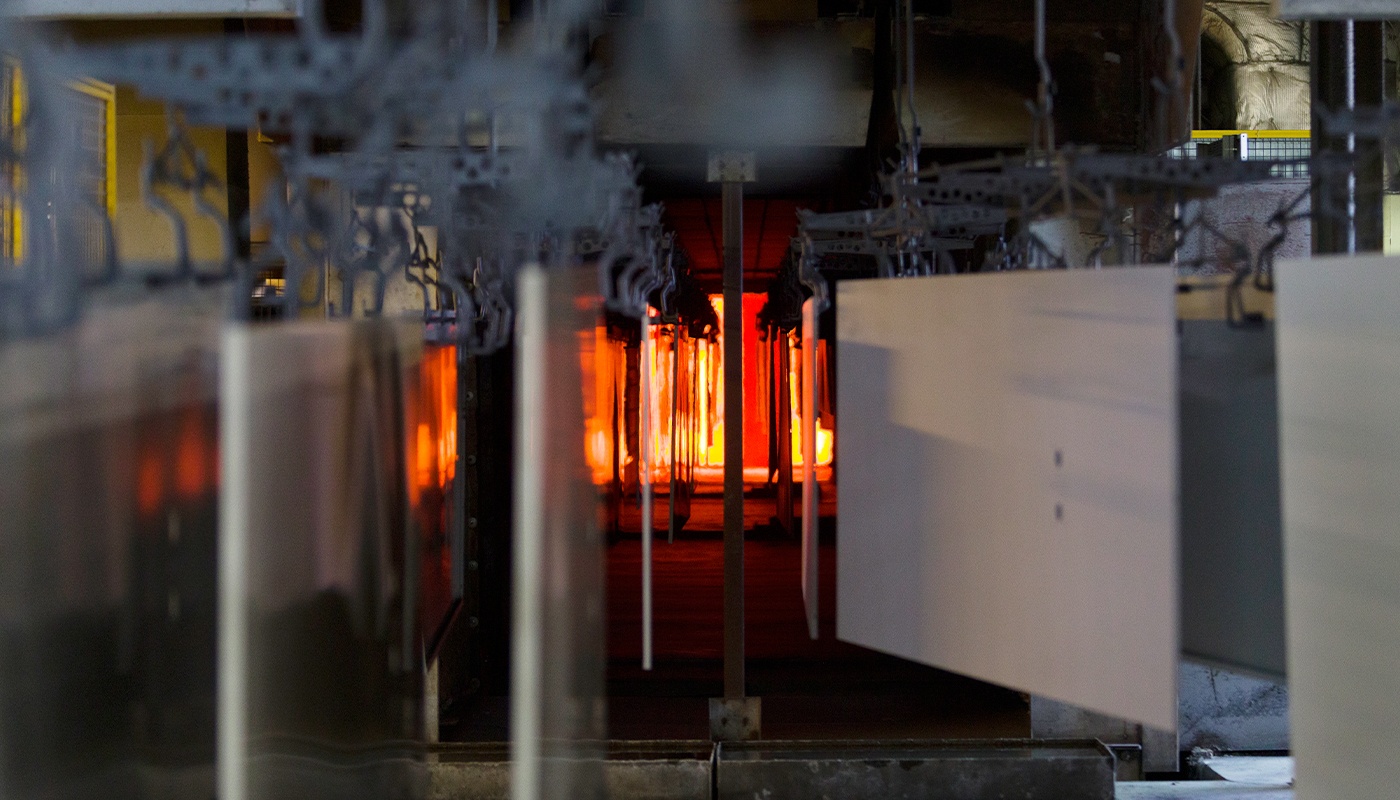

PROCESS 6

PROCESS 6Baking of glaze

The glaze is baked in a firing furnace at about 850°C. The finely ground glass is fused, forming crystals inside the glaze and resulting in enamel with enhanced color and a smooth vitreous surface.

Takara standard technology

Baking temperatures are strictly controlled to match the color of the enamel product.

-

PROCESS 7

PROCESS 7Assembly, inspection, packaging, delivery

Each baked part undergoes strict inspection that involves checking enamel coating thickness and measuring color difference. Takara standard enamel is used in a variety of parts, so it is cut and assembled based on its application and assembled into final products. These are then inspected and packaged before being shipped to customers.

Takara standard technology

Assembly of end products involves many workers, who use their sight and touch to ensure that the products we ship to customers are of the highest quality.

Takara standard’s high-grade enamel boasts a range of applications,

including kitchens, range hoods, kitchen panels (backsplashes), washstands,

bathroom wall panels, and interior and exterior materials.

Enamel is easy to clean and durable so it keeps on looking good.

We believe that enamel’s attractiveness is important

for making products that keep customers happy for years.

Delivering superb products to the customer

At Takara standard, we will continue to grow and fulfill this mission.